PROTOTYP 2

Modell PR-02W

State of the art

A variety of timepieces and instruments already exist in which the crown is lockable so that it can not be rotated inadvertently. In such cases, the elevator crown is manually selected by the user. However, conditions may arise when the watch could be damaged (e.g. when diving, allowing water ingress into the internal housing). In this case, it should be noted that the different positions of the unit have varying levels of waterproofness. It is usually done by screwing the crown, the crown being in a position where it is pulled by the fingers to a first or second position from the housing after the crown has been detached from the fixed thread by screwing it.

Adjusting the time display and winding the watch can be done in a humid environment, and it is to be assumed that the wet hands of the diver permit humidification of the threads, e.g. sand and other small particles can adhere to the thread. When the time display is set under such conditions, there is a possibility that fine foreign particles such as sand or the like can get into the exposed threads and damage them irreparably.

Further disadvantages of such screwed crowns are the relatively long turning of the crown in order to close it tightly or to loosen it for the winding up and setting of the time. This is also the time factor for this operation. Also, the waterproofness of the timepiece is always different due to the uncontrolled pulling force of the crown, causing a certain degree of uncertainty during dives: too much tightening of the crown can permanently damage the rubber seal guarantee.

Description of the invention

The object of this invention is to avoid the above described disadvantages.

Furthermore, a novel winder and time-setting unit is provided, in which the winder and adjusting element are reliably protected against unintended withdrawal. Lastly, these adjustment methods and the time required for the time or pull-up can be significantly reduced. In the this invention, particular attention is paid to the controlled and constant positions of the winder crown. This ensures optimum and continuous water tightness and provides optimum safety during diving.

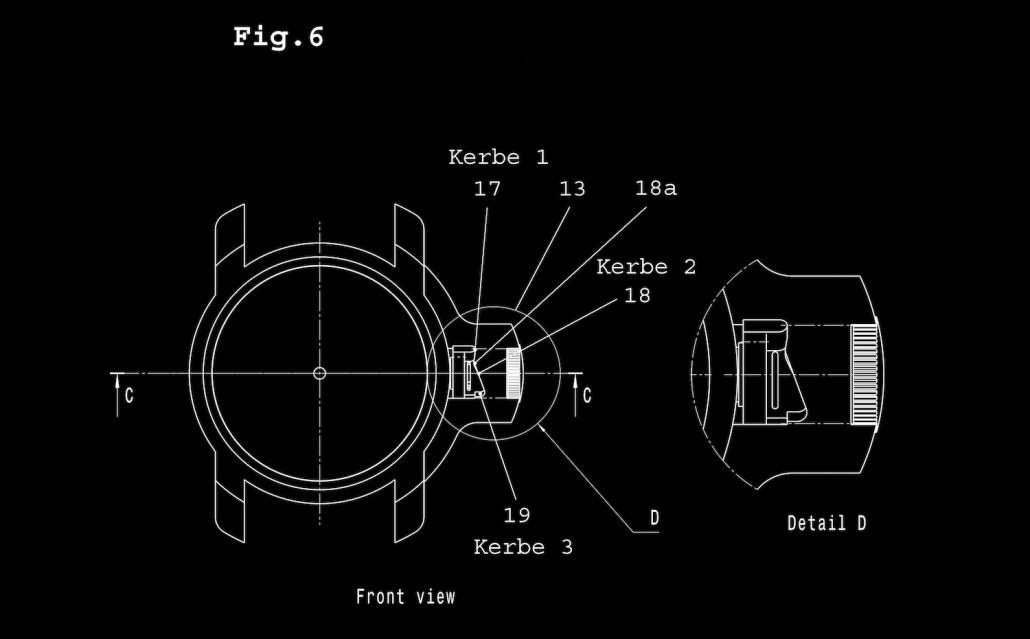

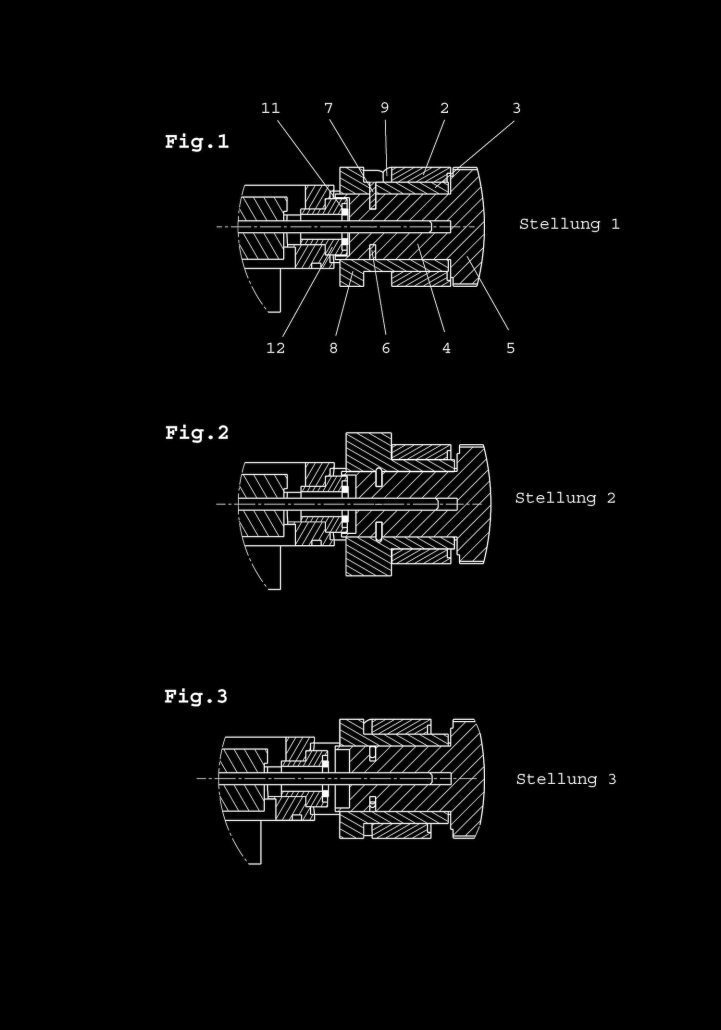

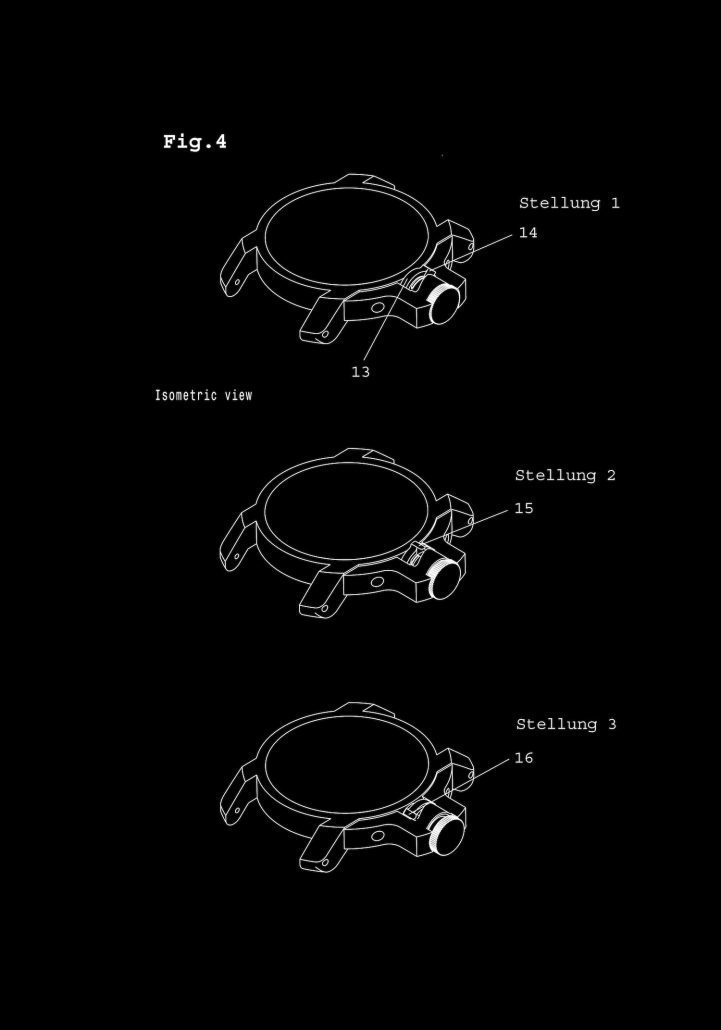

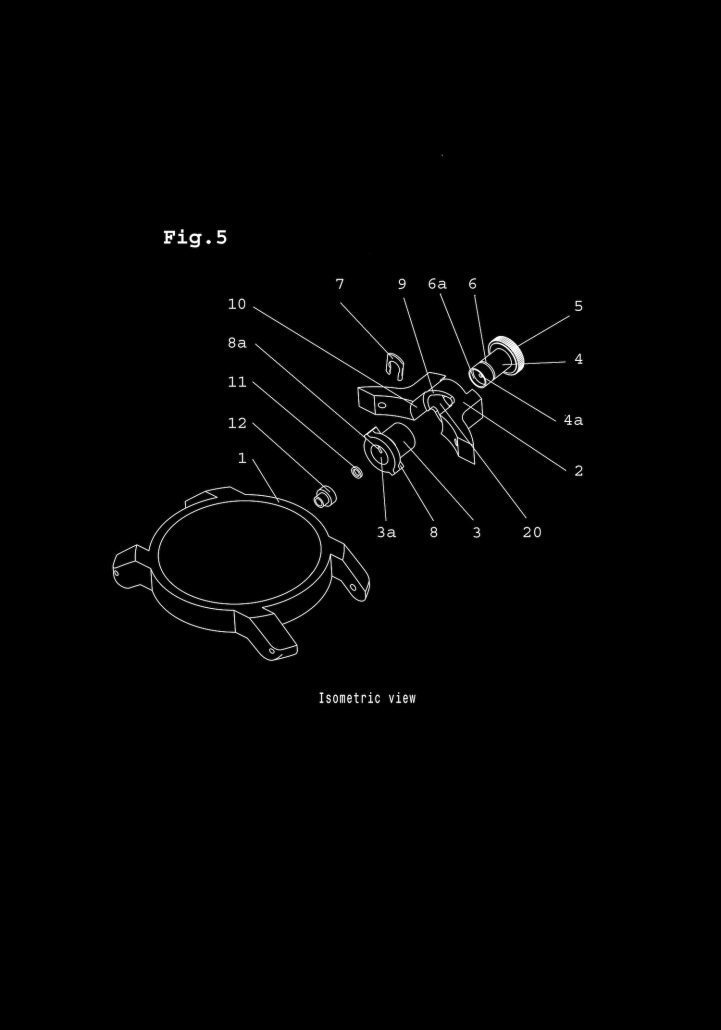

Such a configuration of an adjusting device permits a secure, clearly defined axial positioning of the winder crown (5) in three positions (14, 15, 16) and their safe and rapid changeover. It is important to produce a direction device (20/2, bevel, notch) for the winder movement lock (protrusion) (8) as well as an outward biasing in the axial direction to thereby ensure the fixed setting positions.

In the position 1 (14) (normal position, watertight, closed) of the adjusting device (13), the winder movement lock (protrusion) (8) of the sliding and turning locking lever (3) lies in the position notch 1 (17) .

In the position 2 (15) (winder function of the winding and time setting crown 5 of the adjusting device 13), the winder movement lock (protrusion) (8) of the sliding and rotating locking lever (3) is located in the position notch 2 (18) of the bridge unit (2).

In the position 3 (16) (time adjustment position) of the adjusting device (13), the winder movement lock (protrusion) (8) of the sliding-rotary locking lever (3) rests in the position notch 3 (19) of the bridging unit (2).

By means of this axially applied pretensioning and the defined sliding surface (9) for sliding and turning locking levers (3), it is possible to provide a reliable setting changeover and a secure sealing of the unit in position 1 (14).

Further advantages and features of the present invention are explained in detail with reference to the following figures and descriptions.

For further information, please refer to Patent Specification DE 10 2013 016 273 A1 on the page www.dpma.de

This post is also available in: German